Core Tech

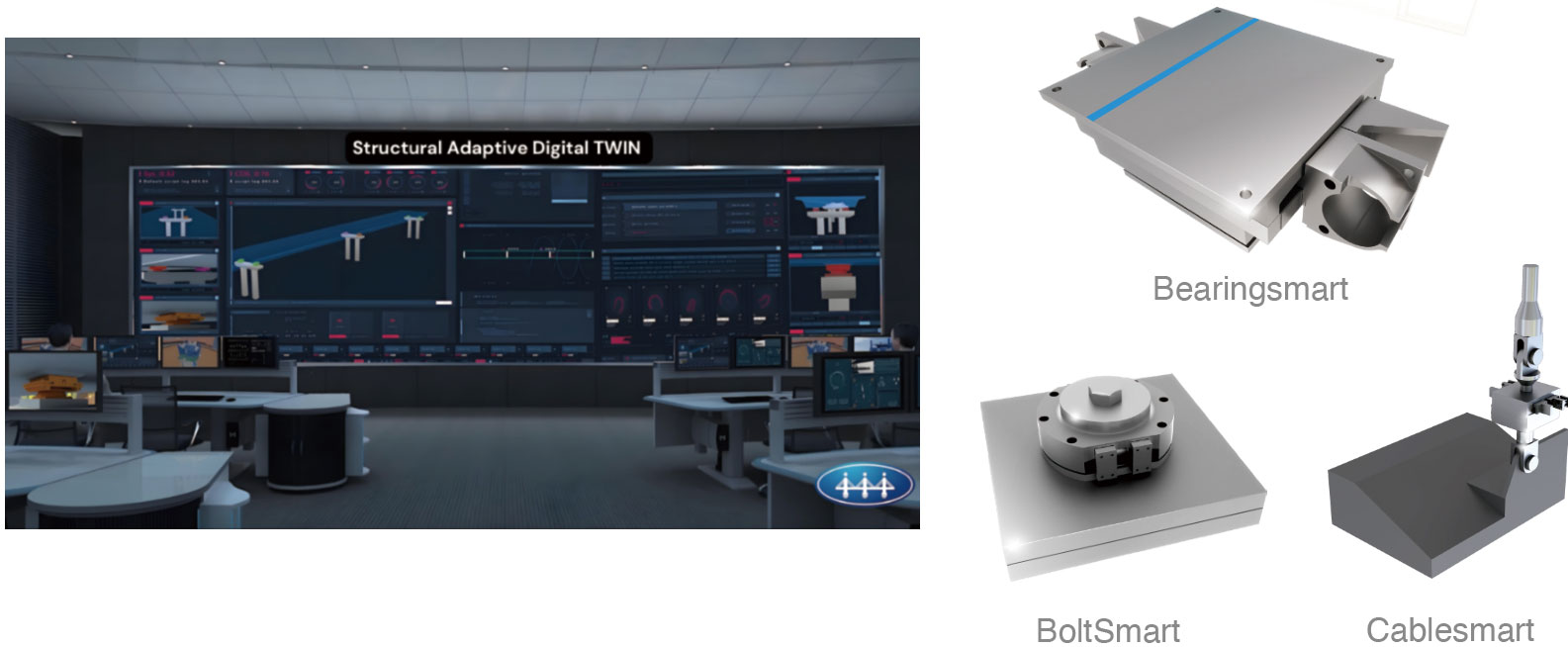

Besides our engineering excellence, our key technology, TWINSA (Adaptive Digital TWIN with Smart Adapter), comprises two core elements:

Intelligent Critical Connector:

Through a groundbreaking metrological innovation called In-Situ Dual Calibration (ISDC), we've developed the world's first technology to provide reliable in-situ calibration for load monitoring and controlling of critical connectors such as bearings, cables, and bolts. This establishes dependable lifecycle load monitoring and controlling for critical connectors.

Adaptive Digital TWIN:

Leveraging Intelligent Critical Connectors, this digital twin system offers not only data-driven insights and evaluations into boundary conditions and hence deeper understanding of a structure's current state, but also adaptive capabilities to optimize load conditions in-situ. By transitioning structures into adaptive systems, it greatly enhances structural longevity and safety, reduces initial construction costs and maintenance costs, and contributes to a lower lifecycle carbon footprint.

With over 40 patents and more than 20 project experiences spanning bridges, buildings, and slopes, we're confident this technology will revolutionize the design, construction, and maintenance of structures.

"Except for the patents held by the commissioning organization of this project, there are no reports in the global literature of a calibration technology for force-measuring devices that allows for calibration under load without altering the position or load-bearing condition of the device."

TWINSA system can be used in bearings (Bearingsmart), cables (Cablesmart) and bolts (Boltsmart). In different applications, TWINSA provides the key to understand actual boundary conditions.

Three 14,000-ton Smart Pendulum bearings (supplied by IEC Inc., the world's largest by load capacity) are installed. Their high load and stiffness make the load distribution highly sensitive to sub-millimeter height variations.

The wind turbine tower is anchored to the base using high-strength bolts. Even tion will be achieved during installation, but various factors such as vibrations can cause changes in the bolt preload force.