We use cookies to enhance your experience. Read our policy so you can understand the types of cookies we use, the information we collect using cookies and how that information is used.Privacy Policy

Close

Confirm choices

Invented in West Germany in 1959, Pot Bearings now serve countless structures throughout the whole world. The first Pot Bearing began its service since 1962 for the B42 Highway in Germany and till today it still operates to its design functions.

Details

General information about

General information about

structural bearings

A structural bearing is a mechanical device of a construction structure, which typically connects the substructure and substructure. It is used to provide structural restraints, specifically, transferring vertical and horizontal loads from the superstructure into the foundation whilst a certain amount of design translation and rotation (twisted) between structural elements is allowed as designed.

Bridge bearings connect bridge piers to the bridge deck. The appropriate selection of bridge bearings has been always a significant subject in construction engineering. There are many types of bearings which have been commonly used along with research and development of the industry. Before 1960s, the most commonly used bridge bearings were made of steel elements and nowadays a variety of different types of bearings has proven their value and largely applied, among which Elastomeric Bearing, Pot Bearing, and Spherical Bearing are the most worldwide acknowledged and employed in design and fabrication.

Pot Bearing

Using history

Invented in West Germany in 1959, Pot Bearings now serve countless structures throughout the whole world. The first Pot Bearing began its service since 1962 for the B42 Highway in Germany and till today it still operates to its design functions.

Decades of history have proven the reliability and durability of these devices. From the smallest size of 500 kN vertical load, Pot Bearing nowadays can achieve up to more than 100 MN vertical load. The largest ever known Pot Bearing has a vertical loading capacity of 106.5 MN.

Pot Bearing was introduced into China in 1970S and firstly applied in a railway cable-stayed bridge in 1979. Since then, Pot Bearings have been developed as a verified means to connect the superstructure onto its substructure and largely used in civil projects ever since.

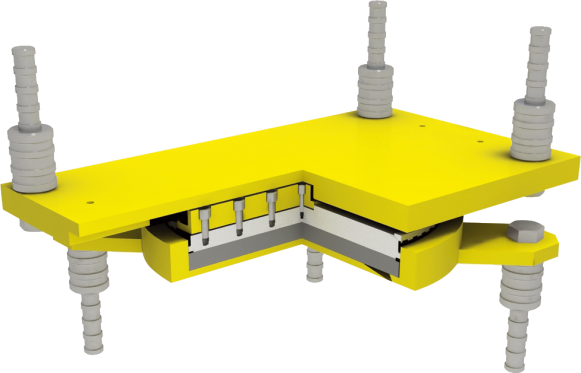

Design principle

Pot Bearing consists of a steel pot, filled with an elastomeric disc and a piston plate (lid). The elastomeric disc is used to support an almost limitless vertical load. The elastomeric disc is made of rubber and behaves similarly to a liquid while its volume simply does not change during compression. It has a Poisson’s ratio of 0.5. The load is also able be uniformly distributed to the pot and rotations can occur, due to the feature of liquidity and flexibility.

The disc is sealed by typically brass rings, which are important element to confine the disc in the pot so it does not escape. Horizontal forces are transmitted from the piston to the pot. To release one sliding direction, an additional element, acting as a guide bar, becomes necessary for these guided-sliding bearings. A sliding material (usually PTFE or UHMWPE) is recessed on the top of the piston plate and slide against the stainless steel plate connected to the bottom surface of the top steel plate.

PTFE is a plastic with high mechanical and chemical resistance, great roughness and low friction when combined with polished stainless steel.

Particular bearings can also be designed using this principle to cater for other combinations of loads such as lifting force or extra high horizontal force.

Design rotation for common pot bearing shall exceed±0.02 rad. Coefficient of friction of sliding parts shall be designed no more than 0.03.

Applied standards

European Standard: EN 1337-5;

China specifications JT391-2019 Pot Bearing;

British Standard: BS 5400-9.1, BS 5400-9.2;

American Standard: AASHTO LRFD Bridge Design Specification and Construction specification

IEC was awarded CE certification for Pot Bearings as per EN standard by KIT MPA Germany and the certificate of Performance of Constancy was cycled till date. We can also design and fabricate as per other standards and specifications.

Advantages of using Pot Bearings

Ø Extremely limited vertical deflection, comparing with elastomeric bearings but with much higher load capacity.

Ø Equal distribution of loads. An array of Pot Bearings along piers can undertake the loads uniformly since the compression of each Pot Bearing is negligible. Elastomeric bearings vary at a comparatively large compressive.

Ø Minimal eccentricity. Tilt causes slight deformation. Such resistance to the deformation is so small that the eccentricity is no more than 3% of the disc diameter.

Ø Low contact pressure requirement. Additional larger size attachment plates can be added to the pot and top of pot bearings to distribute the load. This can facilitate the situation where not high compressive material is used.

Ø More horizontal load can be achieved by adding the size of pot parts with appropriate designs. Max. horizontal load can be designed as high as vertical load.

Ø Technological advantages in fabrication process because of the uncomplicated design.

Types

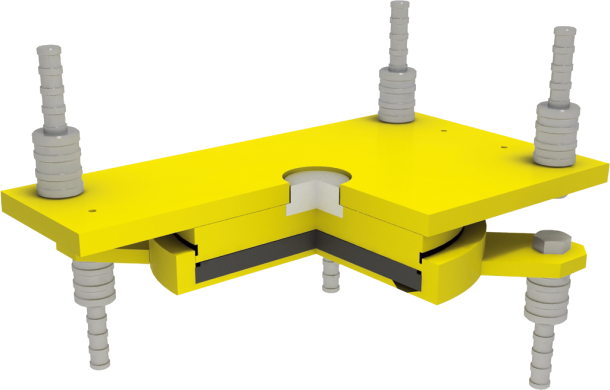

Like any other bearings, Pot Bearing can be types of Fixed, Guided-sliding, or Free-sliding.

a free sliding pot bearing (typical design) a guided sliding pot bearing (typical design, center guiding) a fixed pot bearing (typical design)

According to different requirement, pot bearings can be attached to top+bottom masonry plates. The anchor methods can be bolt/threaded socket assembly, or shear studs. With masonry plates design consider to simplify the job of future replacement

Design sample showing different methods of anchoring & attachment plates (shear studs also available upon design)

Materials

consult IEC for details

Quality control at IEC

All Pot Bearings produced by IEC are CE certified according to EN1337-5. All the required tests have been fulfilled in the ITT(Initial Type Test) and the FPC (Factory Production Control) is regularly monitored according to the regulations by MPA Stuttgart, Germany, a privileged independent supervisory body in the sector.

The external quality control is guaranteed by the internal quality control, which complies with the regulations stipulated in the EN1337-5 standard.

Strictly following the ITP (Inspection and Testing Plan) ensures the consistency of internal quality control. Contact IEC for the ITP documentation.

IEC Inspectors/engineers checking and putting records on the Process Card

Before Pot Bearings are delivered to customer, performance testing of Vertical load (to 150% of design value) and Horizontal load (to 150% of design value) is carried out at a selected ratio per each project, as specified to suitable standard or project requirement, to verify the compliance performance. The testing report is attached as a part of the delivery.

UT NDT testing on the POT of Pot Bearing Compression and shear load test for Pot Bearing

2 units of compression-shear testing equipment is at the use of IEC’s own laboratory. Max. vertical press reaches 30MN while the shear force reaches 1,2,3 MN respectively. IEC's own in-house lab has been also CNAS qualified to ensure test validity.

Production

4 workshops housing a total of 250 employees for producing steel bearing (including Pot Bearing) represent the massive fabrication capabilities of IEC. Each workshop has the respective assembly line.

A Glance at one IEC workshop assembly line

A Glance at one IEC workshop assembly line

A great number of different types of fabrication machines, at different size levels, is equipped, among which many are the CNC type.

Workshop workers carefully checking the dimension of bearing parts during fabrication process

All pots that are used in Pot Bearings are either cast steel or machined from a single piece of metal. IEC has our own casting mill which guarantees the delivery speed as well as the quality of cast parts.

Each bearing is attached with its nameplate showing the bearing ID and other parameters. The movement indicator is arranged for all the expansion bearing. The indelible mark showing the traceability NO. is stenciled on the bearing plate itself. The temporary fixing device is painted red and has a reminder “remove after installation”

traceability NO.stenciled on all critical parts of bearing Standard looks of finished Pot Bearing

Each bearing is properly handled and packaged with sufficient protective methods according to different situations such as distance, way of transport, bearing size, etc.

Inner packaging and outer packaging of bearings prior to shipment

Corrosion Prevention

Ø For inaccessible surfaces

For unexposed steel surface, such as the inside face of the wall of the pot, need not to be treated.

Ø For accessible surfaces

For exposed steel surfaces (most of the steel surfaces) of pot bearings, corrosion prevention methods must apply.

At IEC, when not specifically mentioned, standard procedure will be hot-aluminum spray followed by 3 times of painting at an overall minimum coating thickness of 240 µm (hot-metal spray 30µm).

Galvanized can be also offered upon request.

All the bolts used as anchors are Dacromet treated while the sockets are oxide or dacromet treated.

Dacromet treated bolts/sockets paint thickness checking prior to assembly

Quotations

Pot Bearings are supplied on a project-related basis only. Customer have to furnish IEC staff with the necessary design parameters and related information for costing purpose. Such information shall include but not limited to:

Ø Max., min., and permanent vertical load and horizontal loads (at ULS and SLS);

Ø Displacements and rotations in both directions;

Ø Allowable contact pressure;

Ø Max. available space for the bearing.

There is no standard quotation for Pot Bearings.

Installation, maintenance and replacment

Consult IEC for details