We maintain close collaboration with the State Key Laboratory of Deep Geomechanics and have

co-founded the Smart IoT Research Center (SIOT Center) to drive innovation in structural

monitoring and IoT systems.

He Mancao, head of SIOT center, is a renowned scientist in Rock Mechanics, with a

focus on landslide and earthquake prediction, earning global recognition. He serves as the Vice

President of the International Society for Rock Mechanics and Rock Engineering (ISRM)

and is an

Academicianof the Chinese Academy of Sciences. As a mentor to Darcy, the

President of IEC, He Mancao guides R&D projects at the SIOT center, particularly in the area of

cable newton force measurement, providing reliable data for landslide predictions.

Our research center also collaborates with leading scientists from various

disciplines, these experts contribute on a part-time and project basis, some being on board of

directors, fostering strong interdisciplinary collaboration.

We are engaging technology cooperations also with leading universities worldwide, Research center to be established worldwide for further explorations of our core technology.

Strong Investment in R&D

We invest over 7% of our revenue into research and development. By 2024, we have

contributed to the publication of 6 SCI-indexed papers, hold 152 patents, and have played a key

role in the development of 4 national-level standards.

IEC and Academician He Manchao from the Chinese Academy of Engineering have jointly established

the Intelligent Monitoring and Control Technology Research Center at the State Key Laboratory of

Deep Geotechnical Mechanics and Underground Engineering.

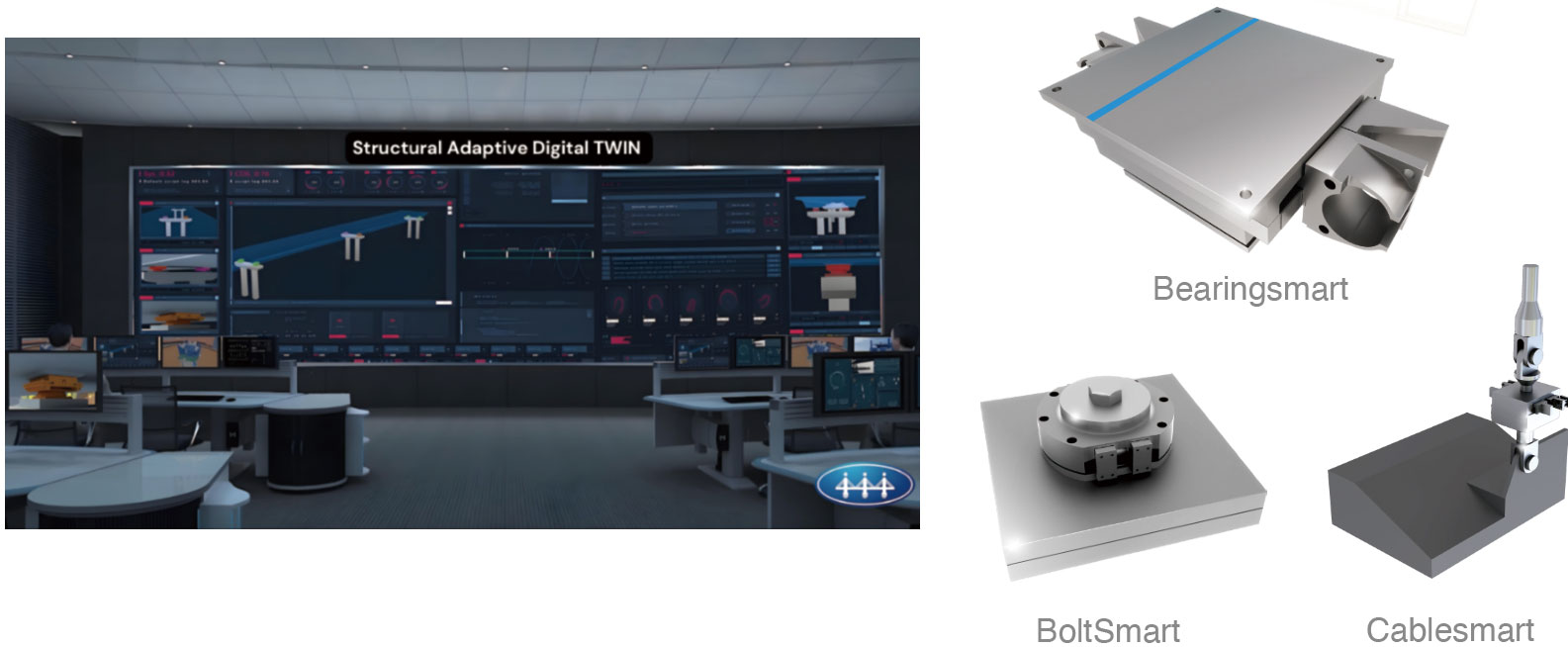

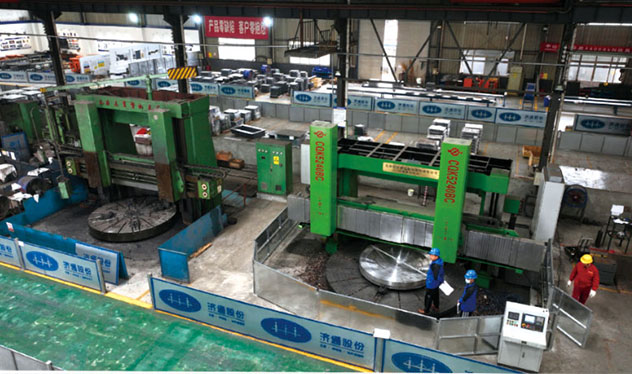

IEC's

In-House Compression-Shear Testing Machine with 30000kN and 5000kN Vertical Load Capacity and

15% Horizontal Load Capability respectively

Significant Growth

Since our inception in 2016, we have consistently maintained an annual growth rate exceeding 40%.

By 2023, our revenue surpassed $42 million USD, driven by growth in our TWINSA technology and

innovative products. Today, we proudly have over 300 professionals across 12 locations in China,

Australia, and Singapore.