TWINSA

Adaptive Digital Twin

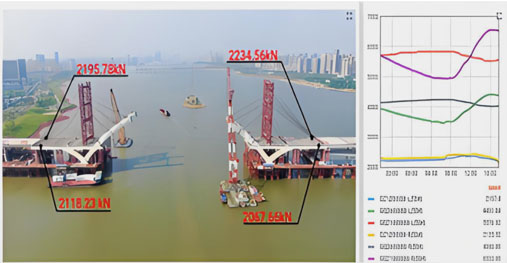

Explicit revealing of structural force transmission mechanisms

Inverse analysis targeting constraint load Reliable model updating

Early malfunction identification beyond conventional:

SHM: Deformation & Dynamic response monitoring

NDE: Defect detection & inspection

Signaling Smart Adapters for constraint adjustments toward structural optimization.

Enhanced ROI via cost reduction (initial & maintenance), extended service life, and carbon reduction.

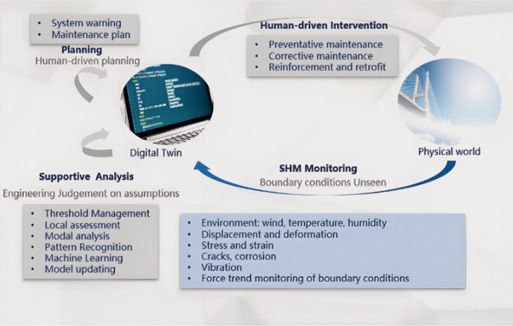

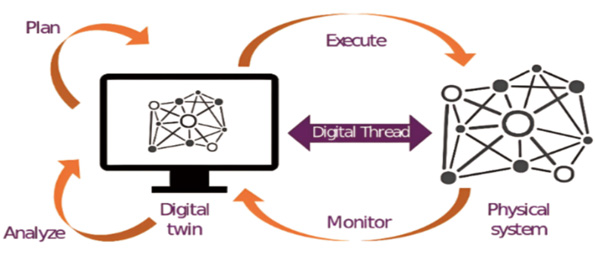

In a traditional digital twin, maintenance and intervention plans are largely manual. This is not only due to the absence of adaptivity in the structure but also because the digital twin’s analysis plays a supporting role, rather than being decisive. Since the system lacks insights into boundary conditions and internal force, it cannot provide a fully accurate picture. Instead, it acts as a mirror to the physical world, reflecting real-world conditions but with limitations. The result is that engineers must rely on their experience and judgment to interpret the data and execute interventions manually, leaving uncertainty about whether the plan is optimal or correct.

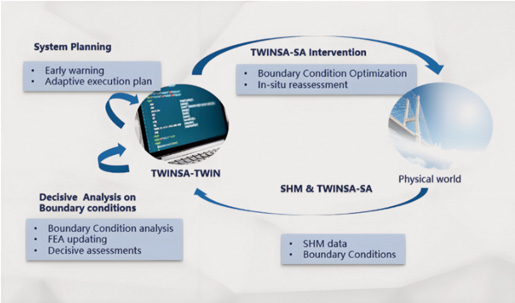

In contrast, the adaptive digital twin goes beyond mirroring. It incorporates real-time data on boundary conditions and internal forces, enabling the system to make automated, systemized pysical interventions. The adaptive twin continuously optimizes the structural model and executes changes directly, ensuring the structure remains aligned with optimal performance across varying conditions. This leads to more reliable, efficient, and self-adjusting maintenance, eliminating the uncertainty present in the traditional approach.