Spherical Bearing

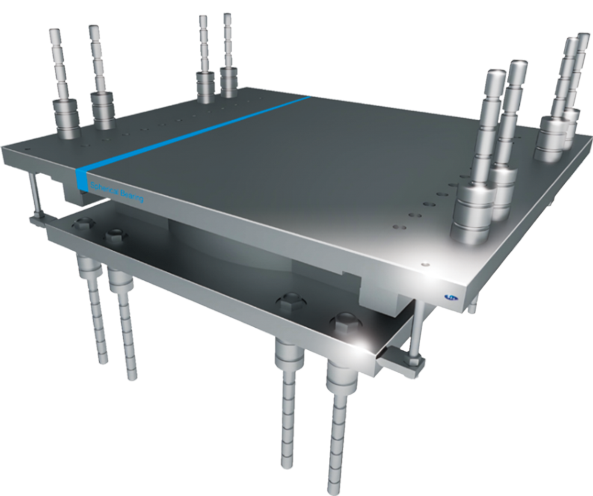

Design Principle

Spherical bearings are engineered to provide exceptional rotational capacity while accommodating both vertical and horizontal loads. Featuring a concave and convex spherical interface combined with advanced sliding elements such as PTFE or UHMWPE, these bearings allow precise rotational and translational movements. This design ensures adaptability, efficient load distribution, and durability, making spherical bearings ideal for large-scale structures that demand reliable performance under dynamic conditions.

Suitable Applications

Quality&Features

IEC’s spherical bearings are designed to meet internationally recognized standards, including EN 1337, BS 5400, and AASHTO LRFD. With CE certification, these bearings reflect IEC’s adherence to stringent performance and safety criteria. The company employs advanced materials, including stainless steel (S304) and innovative sliding materials such as UHPF (Ultra High-Performance Friction), known for ultra-low friction and superior wear resistance. These bearings undergo rigorous testing for rotational and load capacities, wear resistance, and friction coefficients, with third-party inspections ensuring compliance with global standards. UHPF’s self-lubricating and energy-dissipating properties enhance seismic performance while reducing maintenance, making spherical bearings both cost-effective and highly reliable for long-term use.

CATALOG DOWNLOAD