Friction Pendulum (System) Bearing

Design Principle

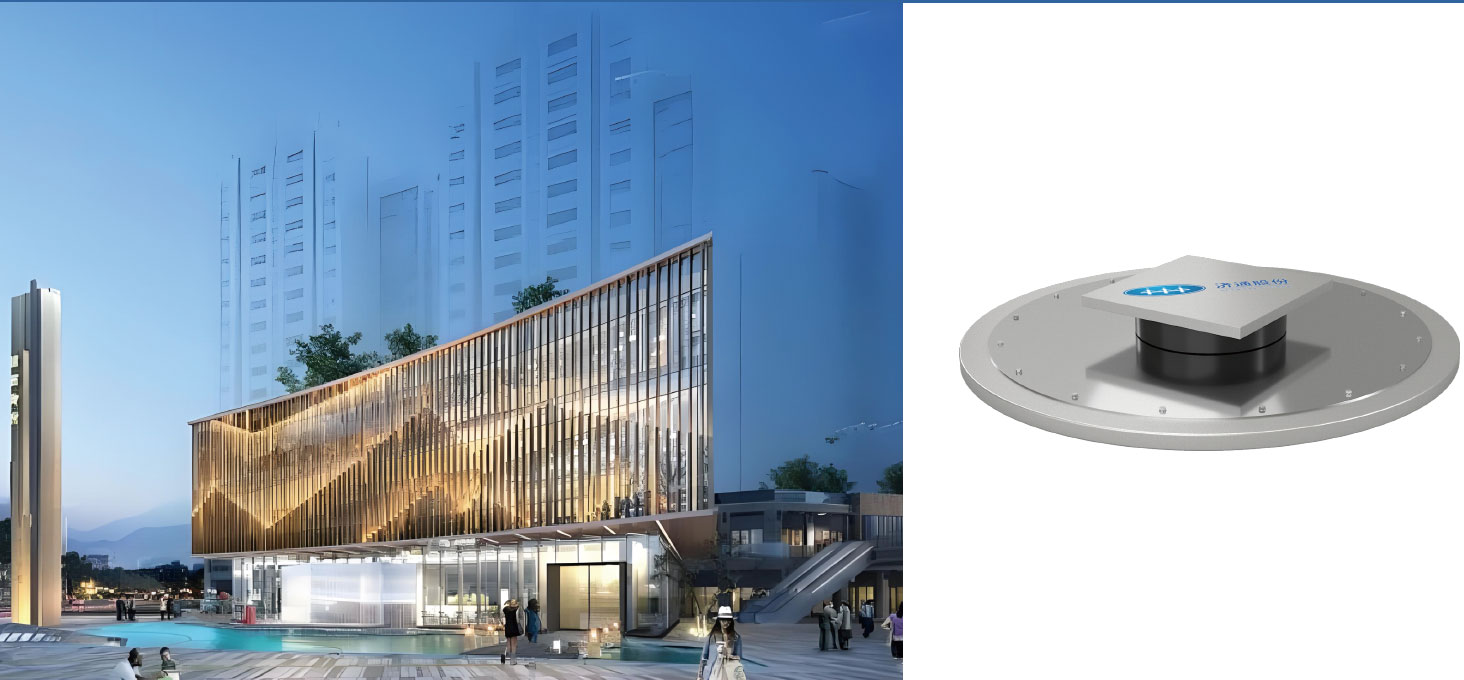

Design Principle Friction Pendulum Bearings are designed to isolate structures from seismic forces by decoupling the superstructure from ground motion. They utilize a concave sliding surface and pendulum action to dissipate energy and accommodate movements caused by seismic events. At the core of IEC’s FPBs is the Ultra-High Performance Fluoropolymer (UHPF), an innovative sliding material that enhances load-bearing and movement capabilities while ensuring long-term reliability and efficiency. Quality & Features IEC’s Friction Pendulum Bearings are CE-certified, adhering to rigorous international standards such as EN 15129 and ISO 3010. These bearings incorporate UHPF, a next-generation material with exceptional wear resistance and a stable low friction coefficient of 0.04, ensuring consistent performance under dynamic loads without the need for lubrication. The material’s durability under extreme conditions, including temperatures ranging from -50°C to +60°C and high compressive forces, makes it ideal for demanding applications. IEC’s FPBs are thoroughly tested for seismic performance, wear resistance, and energy dissipation, with third-party verifications ensuring compliance and reliability. UHPF’s self-lubricating properties further reduce maintenance needs, offering a cost-effective and sustainable solution for seismic isolation. Suitable Applications IEC’s Friction Pendulum Bearings are widely used in bridges, hospitals, high-rise buildings, and critical facilities where seismic protection is paramount. These bearings are particularly suited for infrastructure in seismic-prone regions, providing robust energy dissipation and structural protection. Their adaptability, long service life, and compliance with global standards make them an indispensable choice for modern infrastructure projects requiring advanced seismic isolation.

Suitable Applications

Quality&Features

IEC’s Friction Pendulum Bearings are CE-certified, adhering to rigorous international standards such as EN 15129 and ISO 3010. These bearings incorporate UHPF, a next-generation material with exceptional wear resistance and a stable low friction coefficient of 0.04, ensuring consistent performance under dynamic loads without the need for lubrication. The material’s durability under extreme conditions, including temperatures ranging from -50°C to +60°C and high compressive forces, makes it ideal for demanding applications. IEC’s FPBs are thoroughly tested for seismic performance, wear resistance, and energy dissipation, with third-party verifications ensuring compliance and reliability. UHPF’s self-lubricating properties further reduce maintenance needs, offering a cost-effective and sustainable solution for seismic isolation.

CATALOG DOWNLOAD