TWINSA

Case Study

Transforming Structural Engineering with Adaptive Digital Twin

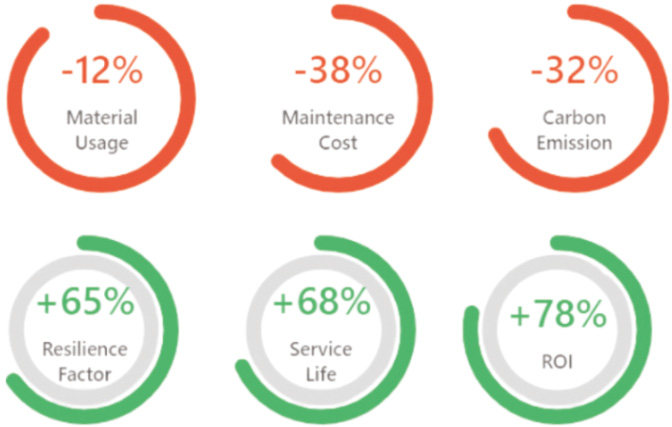

Smart elevate structures to a new paradigm of adaptivity, offering game-changing benefits:

Enhanced Resilience: Ensures balanceddistribution, minimizing stress concentration, maintaining stability during unexpected loads

Increased Safety: Enables early detection of issues for proactive intervention, reducing the risk of failure.

Lower Life Cycle Costs:

Efficient Material Use: Reduces material requirements in design without compromising strength.

Reduced Maintenance: Localized adjustments lower repair costs and allow traffic to continue during maintenance, minimizing disruptions.

Improved Longevity: Localized adjustments lower repair costs and allow traffic to continue during maintenance, minimizing disruptions.

Reduced Carbon Footprint: Efficient material use, extended lifespan, and fewer interventions lower emissions, supporting sustainability.

Twinsa’s potential benefit on LV Continuous Beam Steel Box Girder Bridge*

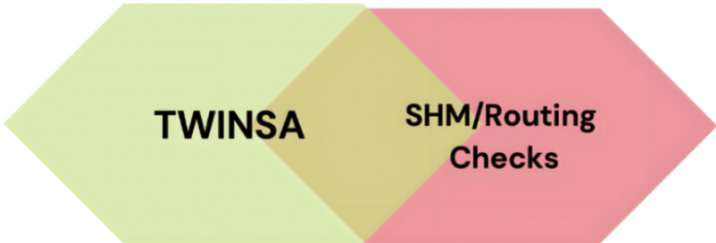

Trustworthy Structural Model Updating,

Identifies suboptimal boundary conditions early with timely warnings,

Management of reliable safety factors

Green / Yellow Lights

Identifies cracks, misalignments, deformations, abnormal dynamic reaction

Supports the TWINSA Adaptive Digital Twin in feeding

Yellow/Red Lights

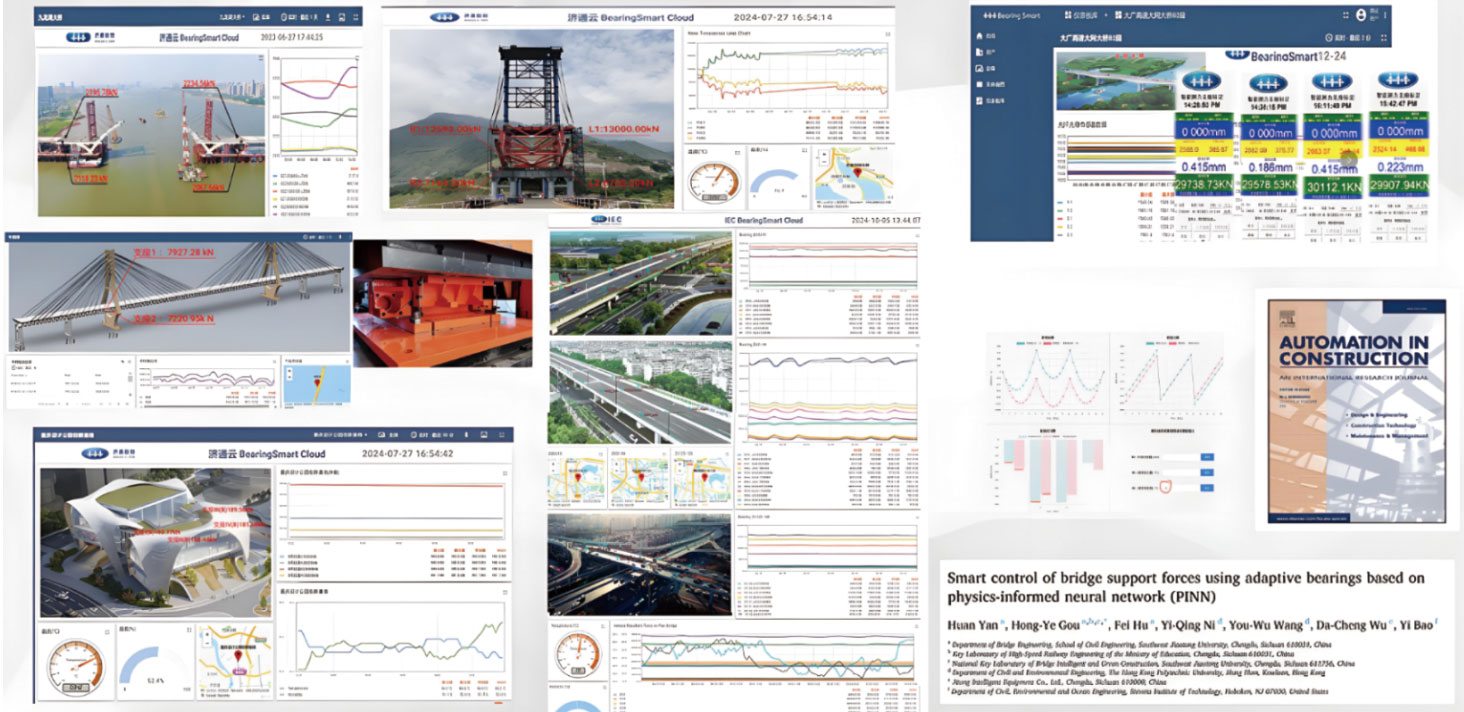

Since its invention in 2020, over 20 TWINSA system-supported IoT systems have been deployed in the cloud, integrated with SHM and pioneering digital twin systems. With 40 patents granted, SCI papers published, and over 2 billion data records generated, the system continues to improve.