TWINSA

Engineering Challenge

Reveal Boundary Force

Routine Inspection, SHM and Digital Twin: Current

Technologies and Limitations

To assess structural safety and functionality, two primary methods are employed: routine inspections and monitoring systems. Visual checks, often assisted by drones or robots, detect cracks, deformation, or corrosion. Non-destructive testing (NDT) techniques, such as ultrasonic and X-ray scans, identify internal defects without causing damage. Periodic load testing assesses the structure's ability to withstand stress and movement.

Structural Health Monitoring (SHM) and Digital Twin

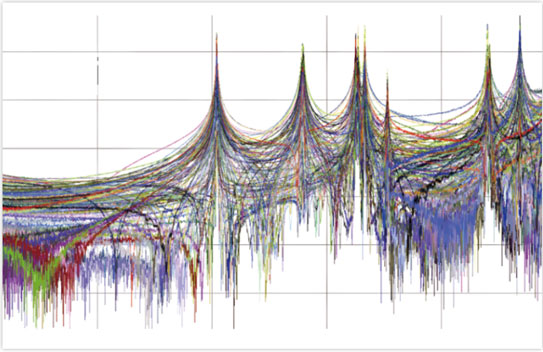

SHM systems use sensors to monitor deformations, displacements, strain, and vibrations, aiming to detect abnormal behaviors and provide timely warnings. These systems often integrate with finite element analysis (FEA*), which simulates the structure’s behavior under various conditions. Modal analysis investigates vibrations to determine the structure’s dynamic properties, and abnormal responses may signal changes in its mechanical state. When SHM integrates with simulation tools like FEA, it forms a digital twin—a virtual representation that offers deeper insights into the structure’s performance over time.

Modal analysis investigates into the vibrations to determine structure’s dynamic property

Limitations of current practice

Although these systems effectively identify local issues such as cracks, corrosion, or material deterioration, they often fall short when evaluating the overall mechanical state. SHM systems typically lack insight into the mechanical conditions of critical connectors, which function as structural boundary points. These boundary conditions are crucial for accurately analyzing internal force throughout the structure. As a result, SHM often relies on assumptions — such as idealized or balanced boundary conditions — that may be far from true conditions or even misleading. This can lead to false-positive or false-negative assessments, despite the use of advanced algorithms and extensive data collection.

SHM lacks insight in internal force