TWINSA

Case Study

Discovery 3: Bearing Functional Failure

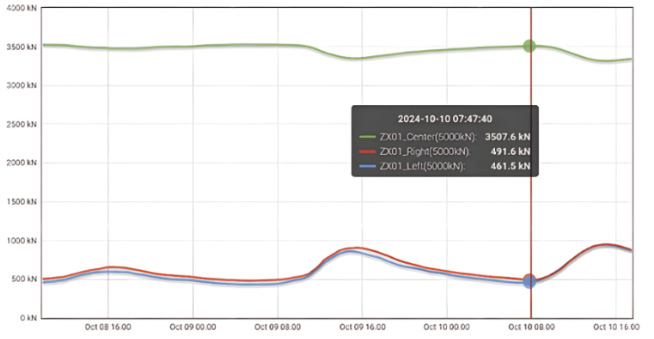

TWINSA discovered that the load on the ZX01- Left and ZX01-Right bearings ranges between 450KN and 980KN, with 550KN attributed to temperature gradients. This raises significant concerns: with a designed load of 5000KN, these bearings are carrying less than 10% of their designed capacity, which is non-compliant with AASHTO specifications requiring all bearings to bear at least 20% of the designed load.

ZX01 bearings carry less than 10% of designed capacity, a functional state of failure

Cause

Based on the TWINSA-supported FEA analysis, a 4mm height difference between the center and side bearings was identified as the cause. Despite measures taken to align the bearing heights, achieving consistent elevation across multiple points remains inherently challenging, even with precision instruments. Additionally, the deformation of the superstructure contributes to uneven load distribution, resulting in bearing forces significantly lower than the design values.

Bearing height control is difficult, and without accurate load monitoring, ensuring proper load distribution is nearly impossible

Plan and Mitigation

TWINSA can automatically develop mitigation plans that optimize internal forces by adjusting boundary conditions. These adjustments may not match the original design values but are optimized based on the actual conditions identified through analysis and model updates. That is the center of the MAPE-K model's K(Knowledge), meaning we get the chance to know the structure better, and to Executve and optimize the physical structure more effectively.

AASHTO LRFD Bridge Design Specifications, 9th Edition, 2020

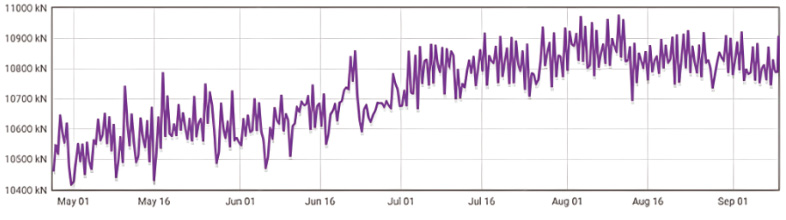

Some bearings showed signs of mid-term change of load states, needs closer observation

The structure was designed in full compliance, but in reality, various factors may contribute to deviations from these assumptions, leading to non-compliance.