TWINSA

Case Study

TWINSA Insights

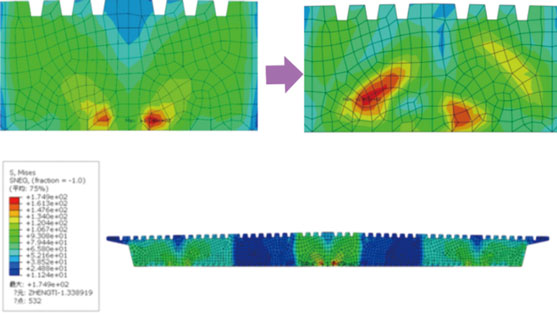

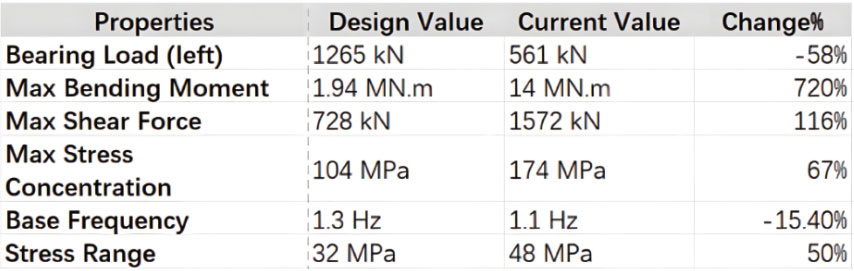

This condition is seriously not compliant with standards. In design stage, the structure was designed with full compliance, but that kind of compliance is based on assumptions. But the real world is not perfect.

Static implications:

Significant shift and increase of transverse bending momentum

Shift of shear forces

Shift and increased stress concentrations

drastic change of structural boundary conditions

Dynamic implications:

Changes in modal properties

Increased stress range Altered seismic responses

Further actionable insights:

Fatigue life projections

Deterioration analysis

Updates to safety reserves

Re-evaluation of structural safety

The maximum stress concentration had a 67% increase from design state, recorded at 174 MPa

Significant changes to structural status under Bearing Function Failure States

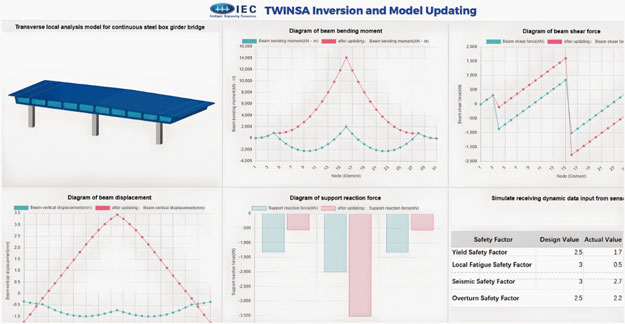

TWINSA Adaptive Digital Twin Inversion platform with FEA API with minimum computational requirements

The TWINSA Inversion and Model Updating Platform uses well-defined boundary conditions monitored, streamlining model updates and enhancing computational efficiency. Unlike traditional methods like Frequency Response Functions (FRFs), TWINSA simplifies updates by using known forces and conditions. This greatly reduces computational demands while ensuring accurate updates to structural parameters and safety factors, all computed through the FEA API.